Vacuubrand vacuum pumps can now be easily integrated into Lab 4.0 environments thanks to HiTec Zang’s laboratory automation solution.

Co-ordinating the functions of laboratory devices made by different manufacturers is now simpler, quicker and more effective with the latest automation solution from HiTec Zang.

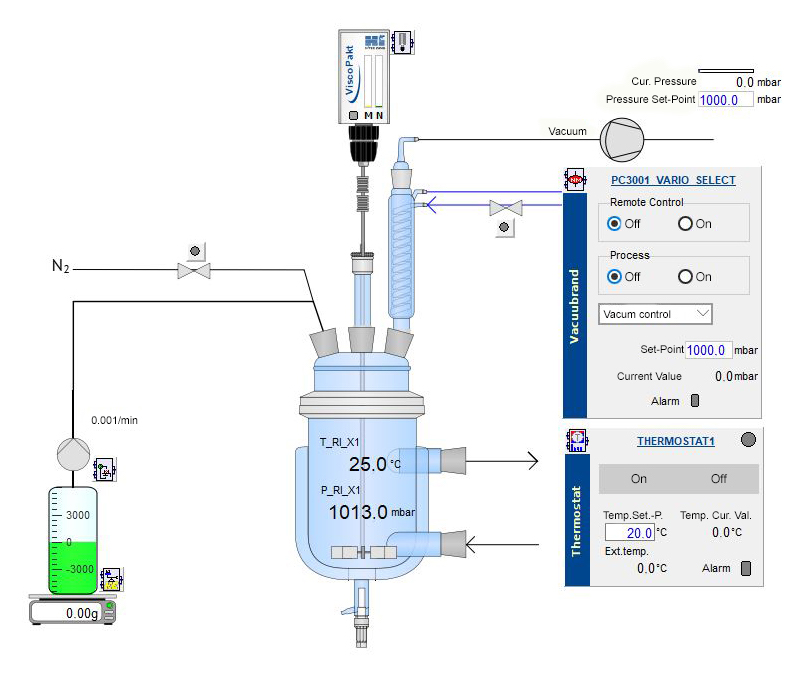

The innovative automation software from HiTec Zang is comprised of the LabManager® laboratory automation system, which can be connected to laboratory devices using a serial or Ethernet interface, and the LabVision® control software, which allows users to visualise, control and monitor their process and process parameters.

LabManager® is a modular interface with over 3,000 possible connections, benefitting an array of laboratory devices, for automation of:

- Temperature, pressure and vacuum regulation

- Stirrer speed and torque recording

- Single and multi-stage synthesis

- Controlled distillation and rectification

- Polymerisation and polycondensation

- Extraction and crystallisation

- Dosing control of liquids, solids and gases

LabVision® is currently best suited for the automation and visualisation of flow and batch processes. The technology has proved useful in laboratories, pilot plants, mini plants and production areas in a variety of industries, including chemical, pharmaceutical, biotechnological and foodstuffs technology industries.

Vacuubrand and HiTec Zang products work together to allow vacuum technology to be controlled by automation software. Vacuubrand’s latest VACUU-SELECT vacuum controller is equipped with the Modbus TCP interface to allow optimal communication with automation software.

What are the benefits of automation?

- “Time-to-market” for new products is reduced

- More efficient utilisation of resources and staff

- Improved quality of final product

- Optimal process reproducibility, even after years

- Reduced risk, potential danger and cost

- GLP/GMP-compliant operation, with no additional effort required

- Complete documentation of the entire process flow

An example of networked lab devices in action

In a Lab 4.0 environment, one typical example of where device integration and automation would be put to use is control of a distillation process. Using the LabVision® software, the user configures the process by selecting the devices that are required for it, such as thermostat, magnetic stirrer or vacuum pumping unit, and the desired parameters are then inputted into each device. The user would then start the process, allowing the automation system to run it entirely, with data being logged throughout.

An illustration of distillation in LabVision®, with integrated vacuum pumping unit:

Contact Labtex today to find out more about vacuum and automation technology from Vacuubrand and HiTec Zang.

Call 01484 600200 or email info@labtex.co.uk.