BANDELIN is a family-owned company located in Berlin specialising in the development, manufacturing and sales of ultrasonic devices, the corresponding accessories and application specific cleaning agents and disinfectants.

BANDELIN devices contribute to the success of customers in the laboratory, medical, dental, pharmaceutical and industrial markets. Laboratory high power ultrasonic devices are used for cleaning, degassing, emulsifying cell disruption, homogenizing and sample preparation.

Since 1955 the company has been developing and manufacturing high-performance ultrasonic devices including SONOREX – Ultrasonic baths and SONOPULS – Ultrasonic homogenisers.

BANDELIN are innovation leaders in the development of ultra-sonic devices having registered 79 patents. As the only complete supplier of ultrasonic devices, accessories, cleaning agents and disinfectants with approvals and certifications according to ISO 9001 and ISO 13485, BANDELIN is the market leader with over one million units sold.

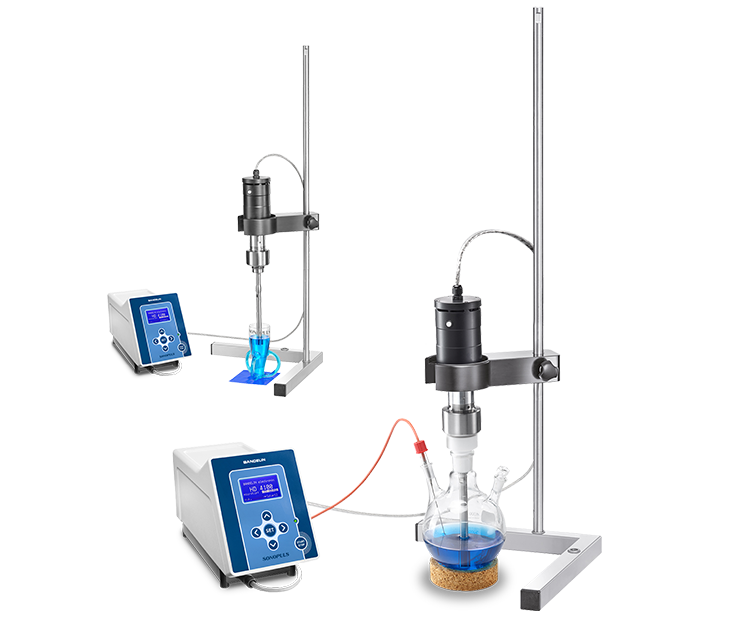

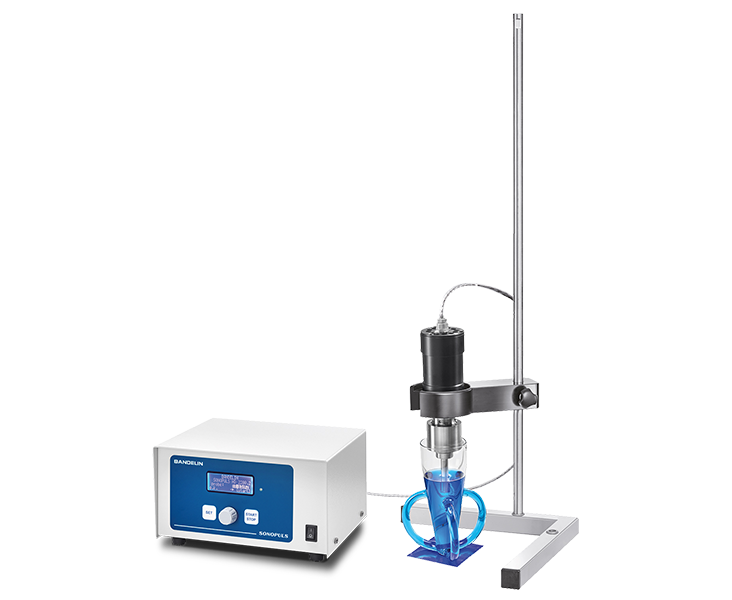

For laboratory and pilot plant use we offer ultrasonic baths and homogenizers with application-oriented accessories for routine cleaning operation as well as for use in research, for sample preparation, cell disruption, emulsification, reaction acceleration or for the production of very fine emulsions.

These cleaning agents were specially developed for ultrasonic applications.

With their cavitation-aiding properties, the special agents support the process and are gentle to the material at the same time. Depending on the cleaning tasks, either alkaline, neutral or acidic cleaning agents are recommended. They are biologically degradable and easy to dispose of. Rinsing after cleaning is necessary to remove remaining residues of cleaning agents and diluted soil particles from the parts to be cleaned.

Show Less

Using ultrasonic homogenisers certain substances can be selectively destroyed, tedious preparation processes can be shortened and results of many reactions are improved, with many years of experience in the field of ultrasonic homogenisers BANDELIN can assist you in your specific application.

Show Less

Features

Show Less